The Cellular Engine for a Sustainable Future.

Development and Validation

of a Digitally Managed Platform for Scalable, Community-Led Spirulina Production and Biorefinery Platform

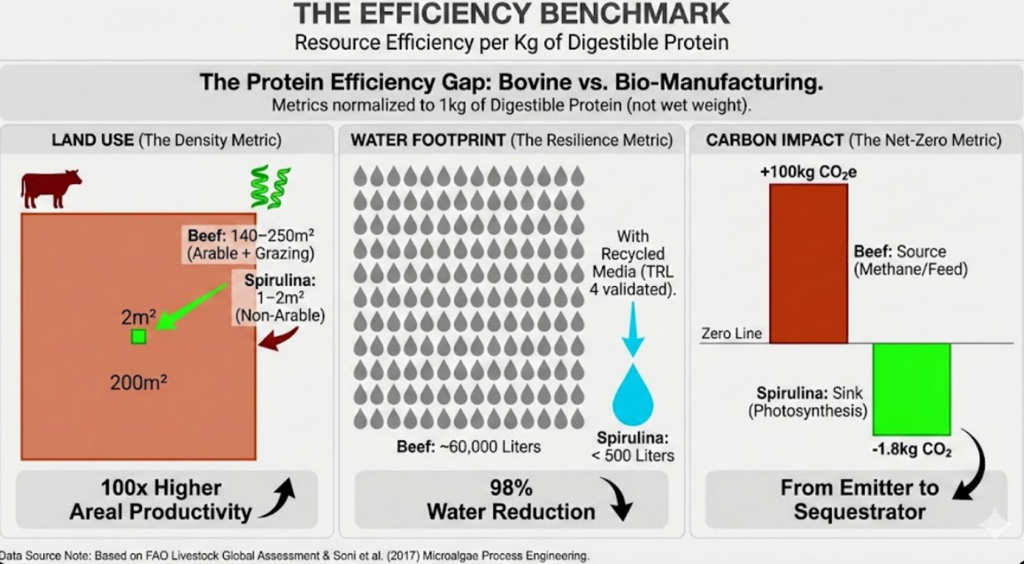

The efficiency benchmark comparing Bovine (Beef) production versus Bio-Manufacturing (specifically Spirulina) highlights a massive “protein efficiency gap.” This gap represents the orders-of-magnitude difference in resource consumption and environmental cost required to produce one kilogram of digestible protein.[1]

Recent studies, particularly those analyzing high-tech production systems (such as the Icelandic geothermal-powered Spirulina facilities studied by Tzachor et al.), utilize this benchmark to demonstrate that bio-manufacturing can decouple protein production from the heavy environmental constraints of traditional livestock farming.

Here is the breakdown of the efficiency gap per kg of digestible protein (or equivalent effective replacement):

1. Land Use

- The Gap: Bio-manufacturing requires ~99% less land than bovine production.

- Bovine: Beef production is the most land-intensive protein source, requiring extensive acreage for grazing and feed crops (often cited between 140–250

m2per kg of meat, or roughly 700–1,800m2per kg of protein). - Spirulina: Cultivated in vertical or stackable bioreactors, Spirulina requires negligible land (<1

m2per kg). It can be grown on non-arable land (deserts, barren rock), avoiding deforestation and competition for fertile soil. - Benchmark: Replacing 1 kg of beef meat with 1 kg of Spirulina biomass saves approximately ~ 340 square meters of fertile land.[2][3]

2. Water Footprint

- The Gap: Bio-manufacturing reduces water consumption by ~96%.

- Bovine: Beef has a massive water footprint, estimated at ~1,450 to 15,000 liters per kg of meat (depending on whether green/rain water is included) to grow feed and sustain the animals.

- Spirulina: Bio-manufacturing systems recirculate water, resulting in a closed-loop cycle. Production uses approximately 50-500 liters of water per kg of biomass.

- Benchmark: Replacing 1 kg of beef meat with Spirulina saves approximately 1,400 liters of water.[2][3]

3. Carbon Impact (GHG Emissions) [4][5][6][7][8]

- The Gap: Bio-manufacturing turns a heavy emitter into a potential carbon sink, reducing emissions by ~99-100% (or achieving net-negative status).

- Bovine: Beef is the highest carbon-emitting food source, generating ~100 kg

CO2eper kg of meat (or ~500 kgCO2eper kg of protein) due to methane from enteric fermentation and land-use change. - Spirulina: Photosynthetic bio-manufacturing consumes

CO2. When powered by renewable energy (like geothermal), the process is carbon neutral.[9] - Benchmark: Replacing 1 kg of beef meat with Spirulina prevents the emission of nearly 100 kg of greenhouse gases (

CO2e).[2][3]

Sources

- nih.gov

- scitechdaily.com

- jpost.com

- dntb.gov.ua

- amazonaws.com

- foodsecurity.ac.uk

- nih.gov

- fairplanet.org

- ioplus.nl

Four Integrated Objectives

1.Laboratory Cultivation Systems optimization and advancement to pilot scale set up through Robust protocols across strains & conditions

2.Digital Quality Control

Predictive, sensor-driven contamination prevention

3.Biorefinery Processing

Value-preserving extraction & drying

4.Alga-QSAR-Prep Platform

Cheminformatics for bioactivity & safety guidance

Cross-Cutting

•Creating a Science based, digitally quality controlled Spirulina Cultivation Hub.

•Community development -STEM & digital literacy for community

•Emerge as a new regional leader in nutraceuticals market, addressing regional malnutrition, etc.

•Open gateway to cost effective and scalable biomedical industries due to its high-level expression of proteins in Spirulina’s Chromosome– Therapeutic proteins, etc.

Our integrated model empowers local communities with scientific knowledge and economic independence, while our UK-based innovation hub, PlanetFix, transforms this nutrient-rich biomass into high-value products—from health supplements and therapeutic drugs to revolutionary biodegradable polymers. We are not just growing algae; we are cultivating a circular bioeconomy that uplifts communities that can heals the planet.

1. The Atmospheric Engineer (Air Revitalization)

Spirulina is an incredibly efficient photosynthetic machine, far superior to higher plants (like wheat or corn) for immediate air recycling.[1]

- The Job: It aggressively scrubs Carbon Dioxide (

CO2CO2) exhaled by astronauts and converts it back into breathable Oxygen (O2O2).[1] - Efficiency: The European Space Agency’s MELiSSA project (Micro-Ecological Life Support System Alternative) has successfully demonstrated that Spirulina photobioreactors can serve as the primary “lung” of a habitat.[1] Because it is a microorganism, it has almost zero non-productive biomass (unlike plants where you have inedible roots and stems), meaning nearly every cell is working to produce oxygen.[1]

2. The Waste Management Officer (Water Recycling)

On Mars, water is more precious than gold.[1] Spirulina thrives on what humans discard.[1]

- The Job: It can be cultivated using wastewater (urine) and gray water.[1]

- The Process: Spirulina consumes the Nitrogen and Phosphorus found in human waste, effectively treating the water while fueling its own growth. This closes the “nitrogen cycle” within the habitat, turning toxic waste back into valuable biomass without the need for heavy chemical filtration supplies from Earth.[1]

3. The Radiation-Proof Nutritionist

Mars lacks a magnetosphere, exposing astronauts to dangerous cosmic radiation. Spirulina is uniquely qualified to handle this.[1]

- Nutritional Density: It provides a complete protein (all essential amino acids) in a highly digestible form, plus critical micronutrients (B-vitamins, Iron) that prevent anemia—a common condition in microgravity.[1]

- Radioprotective Diet: Consuming Spirulina (rich in phycocyanin and antioxidants) helps protect the astronauts’ bodies from radiation-induced cellular damage.

4. The Construction Worker (In-Situ Resource Utilization)

This is the cutting-edge “employability” factor: Bio-Manufacturing Construction Materials.

- The Job: Recent studies (including those by the University of Manchester) have shown that Spirulina biomass can be used as a bio-binder for Martian regolith (soil).[1]

- The Result: When mixed with Martian dust, Spirulina proteins act as a glue, creating “Bio-Bricks” that are stronger than concrete.[1] This allows habitats to be built using local materials rather than hauling heavy structures from Earth.[1]

Verdict: Hired.Spirulina is the ideal multi-tasking employee for Mars. It eats waste, breathes out oxygen, provides complete nutrition, protects against radiation, and can even be used to build the walls of the colony.[1] No other biological organism offers this level of utility per kilogram of payload.[1]

Sources